Injection Molding

Injection Molding

Injection molding involves heating plastic to high temperatures sometimes in excess of 600 degrees and forcing the liquid plastic under extreme pressure and clamping force into a steel mold. The mold is then rapidly chilled and the part is ejected all within seconds. Injection molding is the ultimate method for high volume part production where complex geometry and high levels of 3D detail are required.

Injection Molding Machine

Our capabilities

- 75 – 600 ton molding machines

- process a wide range of materials

- 2 grams – 64 ounce shot weight

- part design and CAD services

- SLA modelling 3D printing

- U.S. and offshore mold manufacturing

- 24 hr / 7 day production

Materials

Depending on your requirements, literally thousands of materials can be injection molded. These range from polypropylene used for toys to ABS used in consumer electronics to nylon used for engineering grade applications to silicone used for high heat requirements and to glass reinforced for extra strength. The options are endless.

Plastic Resin

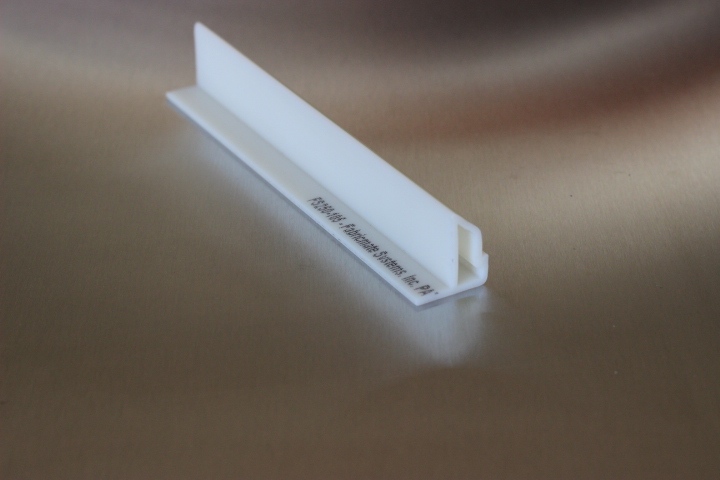

Injection Mold

Advantages to injection molding

- parts with complex geometry are easily achieved

- cycle times are fast making parts cost effective

- multiple parts made in one mold meets production demands multiple cavity or family mold

- close tolerances are easily met sometimes under .001 of an inch

Special characteristics of injection molded parts

- reinforced with glass or graphite – exhibits metal characteristics

- resistant to extreme hot or cold -40 to 500F

- resistant to caustic chemicals and UV exposure

- low CLTE (co-efficient of linear thermal expansion) good for outdoor applications)

- exhibits rubber like characteristics when using thermoplastic elastomers

- anti-stat inhibitors

- chrome plating for automotive applications

Injection Molded Plastic Bin

Fabrication and machining for our customers requiring low production or prototyping. We offer a complete machining facility. Our services extend to SLA (3D printing) and CAD model file capabilities. SRG can assist with design and engineering to insure high quality and cost effective parts.

Plastic Machining

Capabilities

Precision cutting – minimum 6 ” +/- .020

Machining – Prototypes or short run – no die or mold cost

Fabrication – Drilling routing punching notching mitering

Printing – One color random repeating image done inline

Foil – Done inline applies metallic colors or wood grain

Taping – Inline or offline application double sided tape

Special packaging – Consumer products – kitting

SLA modelling – Computer driven 3-D prototypes

CAD services – Full 2-D or 3-D drawing files

Inline Laser Printing

Gold Foil Decoration