Design aids

How to design plastic extrusion for optimum quality and cost effectiveness

Application Any profile such as a channel or tube can be extruded.

Part Design Avoid multiple enclosures. Eliminate mass where possible this contributes to uneven walls. Uniform walls are key.

Thickness Ideal thickness is 030 – 080. Thicker walls up to .250 can be extruded.

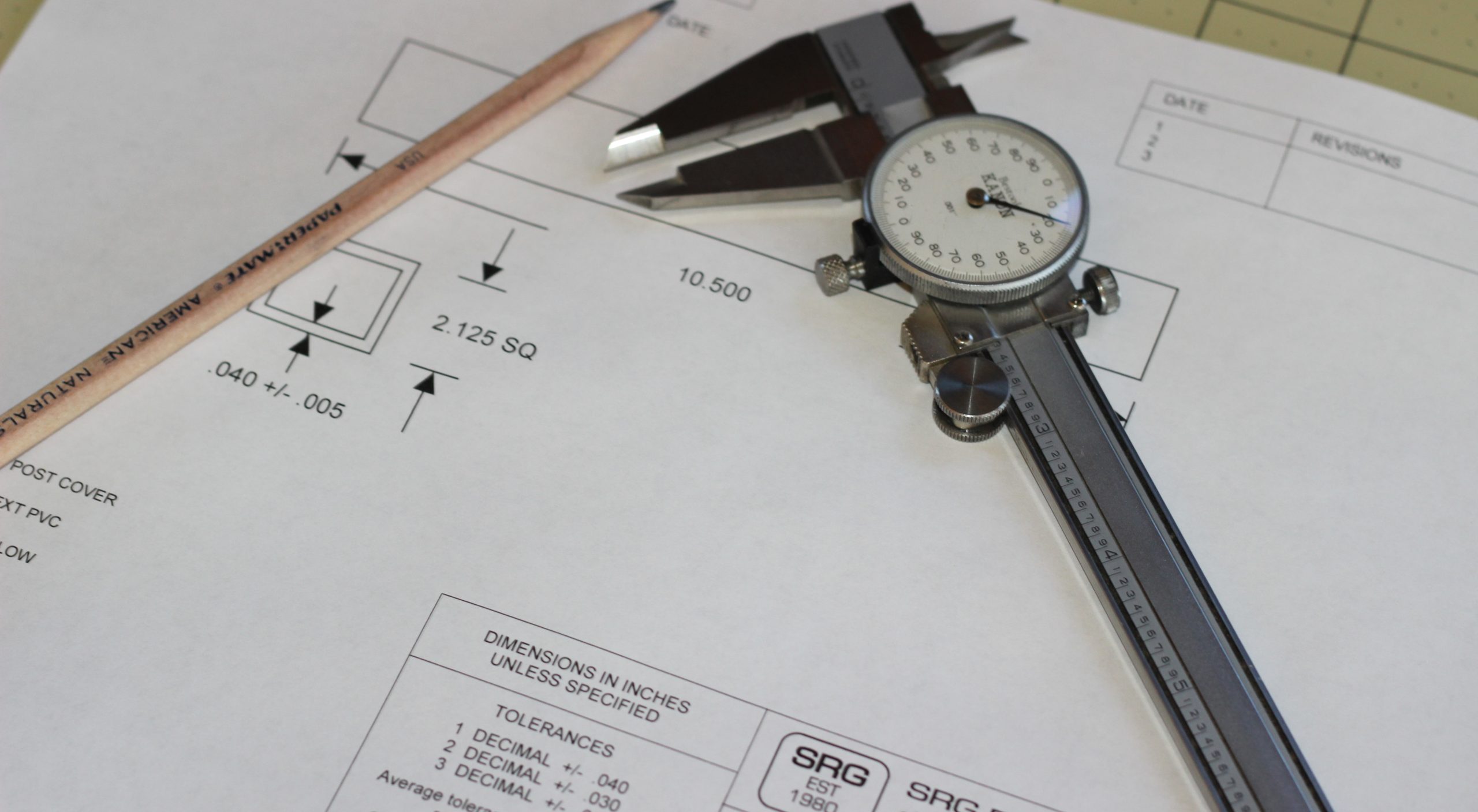

Tolerance The wider the tolerance the faster the extrusion can run. 1-2% of the dimension is ideal. Avoid unnecessary thick walls.

Materials Some materials process easier than others. Some materials require more sophisticated dies and forming equipment.